Commercial Services

Electrical

Benefits:

- Moistureless cleaning

- Successful in completely cleaning electric motor windings in place

- Drying process not required

- No disposal issues

- Potential damage to any components is eliminated

Dry Ice blasting can be used on various parts of electric motors and equipment including:

- Housings

- Stators

- Wiring

- Windings

- Circuit Breakers and Boards

- Electric Production Equipment

- Electric Control Cabinets

- Circuit Breakers and Boards

Power Generation & Utilities

Benefits:

- Power interruptions to clientele eliminated or reduced

- Cleaned and Improved system reliability

- Switching not required improving overall safety

- Reduced necessity for containment reclamation of grit or solvent

- Cleaning can be done anytime of the year

Proactive maintenance helps avoid failures in electrical equipment. Dry ice blasting will successfully maintain the following power generation equipment:

- Switch Gear

- Turbines

- Windings

- Transformers

- Substations

- Line insulators

Tar, Grease, Oils & Petroleum

Method of Removal:

- A methodical approach similar to hosing down a driveway is required if dry ice is to be effective on oil and gel type contaminates.

- You must start at one end and work the grease or oil to the other end where it can be captured by an absorbent cloth or be vacuumed or squeegee for disposal.

- Paper or a plastic drop cloth can be used to catch the contaminant as it is removed from the substrate.

- Dry ice doesn’t dissolve the oil or make it disappear.

- An acceptable method of handling the contaminant is required when it is relocated by the dry ice blasting process.

- Viscous materials are very readily removed by Premier Line Services.

- There is, however, a potential for reposition. Light oil on an accessible flat surface may be removed at up to 20 Sq Ft. Per minute while heavier “pure” grease may be limited to approximately 4 Sq. Ft. Per minute.

- Grease that is being removed from a surface is seldom “pure”. Generally, it has been mixed with dust and production debris and cured by friction and or heat. Removal of this material may be in the range of one Sq. Ft. Per minute.

Tar:

Asphalt tar and related materials tend to contract and lose their bond quickly, particularly on a smooth surface.

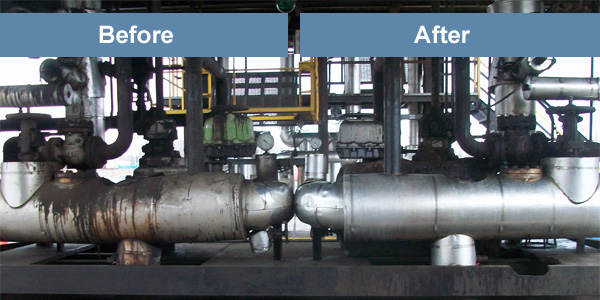

Oil Field Equipment

Reduce cleaning time up to 80%

Benefits:

- Reduces media such as sand from entering process equipment

- Minimizes important equipment downtime

- Eliminates the need for covering and tarping other equipment

- Cleaning process can be done hot, whist equipment is online

- Effectively cleans piping, wellheads, valves, vessel interiors and much more

Cleans oil field equipment thoroughly and safely of the following dangerous contaminants:

- Acids

- Chemicals

- Heavy oils

- Bitumen

- Corrosion